Challenges

-

Landscape Mapping

-

Sustainable materials

-

Supply chain mapping

Client

Innovate UK

Challenge

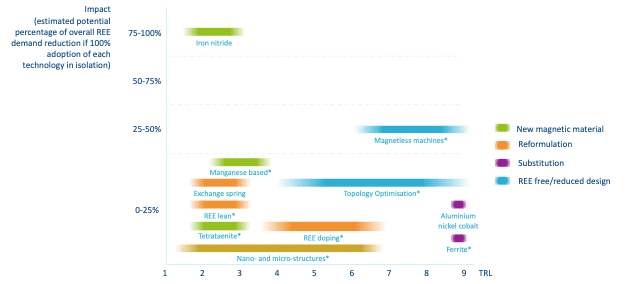

The growing demand for high-performance magnets, driven primarily by automotive electrification and the deployment of Offshore Wind, presents both significant opportunities and strategic risks for the UK. CLT developed reports which reviewed the UK innovation landscape for Rare Earth Element (REE) magnet manufacturing, as well as alternatives to REE-based technologies. They explored how innovation can enhance the UK’s competitiveness while reducing vulnerabilities in the global REE magnet supply chain.

Specifically, the reports assessed the current state of magnet and alternative technology manufacturing, identified key innovation areas, evaluated the UK’s capabilities, and mapped these against sector innovation needs. The objectives of this work were to:

- Identify the UK’s innovation landscape for REE magnets and alternatives, including technologies ready for commercialisation.

- Highlight opportunities to develop and deploy emerging technologies to strengthen domestic capabilities and improve supply chain resilience.

Solution

CLT developed a structured approach to address Innovate UK’s questions, from mapping current capabilities to identifying gaps and setting priorities for action. The key activities included

- Mapping the current ecosystem: Mapping supply chains and processes, compiling a database of UK innovators, corporates, and stakeholders, and assessing existing innovation capabilities (e.g. R&D, financing, testing, scale-up).

- Assessing innovation needs and ecosystem capability to innovate: Identifying sector-specific innovation needs, evaluating the capabilities required for commercialisation, and highlighting key sector barriers.

- Gap analysis and benchmarking: Benchmarking UK innovation capabilities against sector needs and global best practice, and assessing gaps in the UK’s ability to commercialise technologies.

- Recommendation development and dissemination: Developing and prioritising targeted recommendations using a structured prioritisation matrix which mapped innovation needs against the UK’s innovation capabilities. Disseminating learnings through public-facing reports and webinars.

To inform this work, we complemented our desk-based research with over 20 interviews and held two workshops with sector.

Outcome

A range of opportunities to improve the UK’s innovation ecosystem for the REE magnets manufacturing space were formulated and were presented to industry stakeholders for comments and prioritisation. The recommendations focused on the following areas:

Encourage circular design in magnet-using products: Promoting end-of-life disassembly and recycling as core design principles to reduce reliance on virgin REEs and imported magnets, positioning the UK as a leader in sustainable magnet manufacturing.

Fund innovation and skills development: Providing targeted funding to support technology testing, scaling, and workforce training, using grants, loans, equity, or blended finance to overcome barriers to scaling UK magnet manufacturing.

Establish an industry-led working group: Creating a platform for collaboration between end-users, corporates, innovators, and academia to represent sector needs, coordinate information flow, facilitate international engagement, and support quantification of sector demand for REE magnets as well as alternatives to REE-based technologies.

Improve understanding of environmental impacts: Supporting corporates to evaluate the sustainability of current REE magnet supply chains and how local supply chains could reduce impacts, including developing standards to guide sustainable design and sourcing.