A Dual Environmental Threat: Plastics are everywhere. From packaging to products, their convenience has made them indispensable. They are among the fastest-growing bulk materials. But their convenience comes at a steep environmental cost. Produced directly from fossil fuels, every stage of their life cycle contributes to carbon emissions (Figure 1). Compounding this, most plastics do not biodegrade, leading to long-lasting environmental pollution. Plastics pollute twice: first as carbon emissions, then as waste and contamination.

Here we focus on plastic-related carbon emissions, noting that actions to reduce plastic consumption and enhance recycling yield dual benefits.

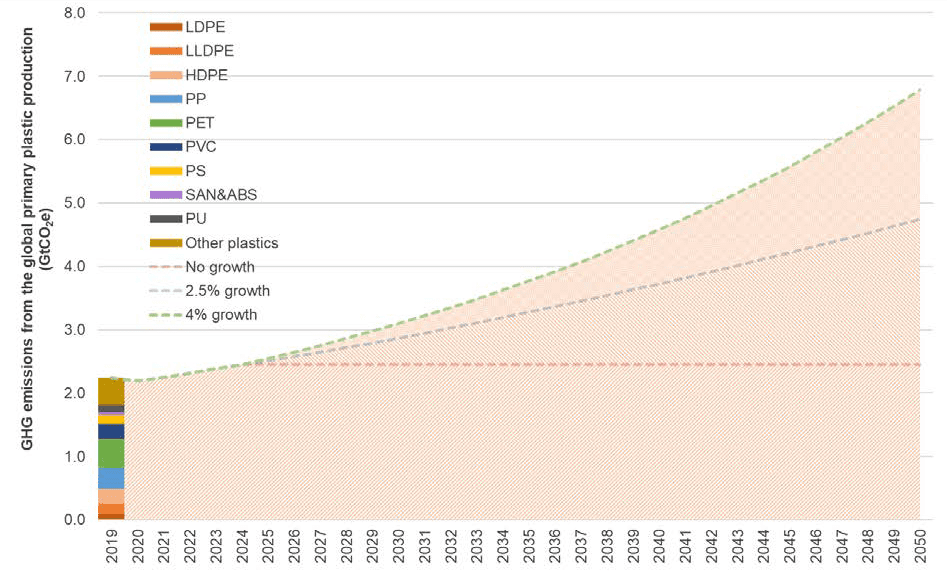

The Challenge – Rising Demand, Rising Emissions: Plastic demand is accelerating, with global production projected to double or even triple by 2050[1]. Oil companies are heavily investing in expanding plastic production as it generates greater revenue growth compared to traditional fuels. Even under a conservative annual growth scenario of 2.5%/y, greenhouse gas emissions from plastic production—currently accounting for approximately 4.5% of the global total[2]—will double (Figure 2). For the UK to meet its Net Zero target by 2050, addressing and eliminating plastic-related emissions will be critical.

Developing a Strategy: Reducing the emissions from plastics requires a strategic approach, since not all solutions are equally effective. The Plastic Waste Hierarchy (Figure 3), a globally recognised framework backed by DEFRA, makes it clear: Prevention is the most effective strategy, followed by reuse.

When waste is unavoidable, recycling is the next best option. Yet, 73% of plastic waste in Europe is still incinerated or sent to landfill, the two most environmentally damaging disposal methods[3]. The UK has a defining opportunity to lead by example, shifting towards prevention, reuse, and a circular economy to cut emissions, reduce waste, and strengthen resource security.

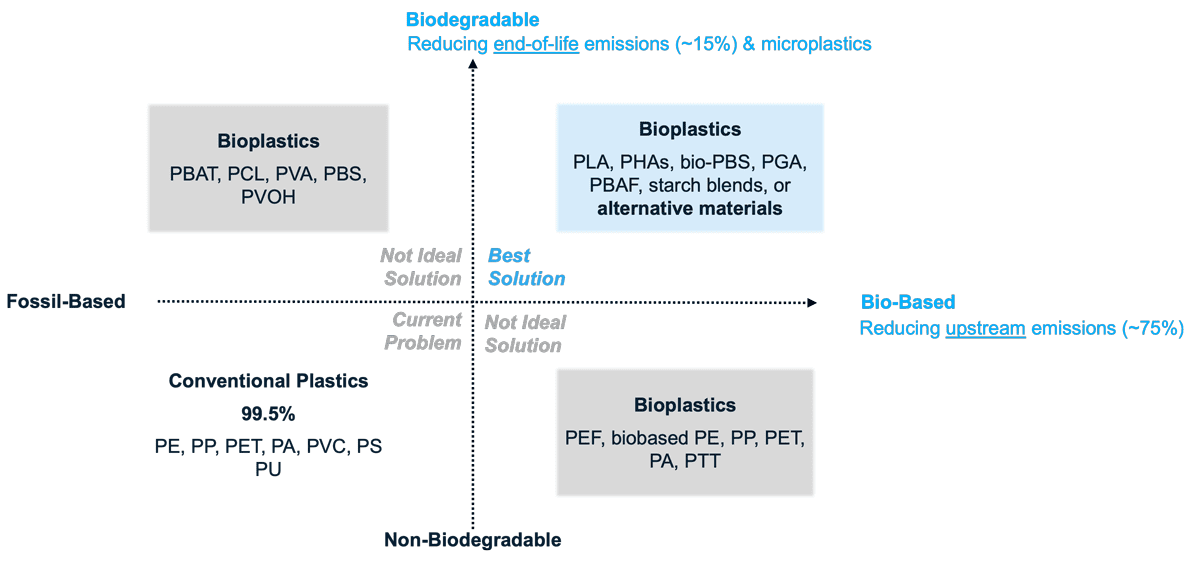

Barriers to progress: The plastics industry faces significant challenges in decarbonisation, and consumer confusion is a major obstacle. For example, terms like “bioplastic” are often misunderstood, leading to improper disposal. Under EU definitions, bioplastics can still be fossil fuel-based or non-biodegradable, misleading consumers and policymakers alike.

In addition, plastics come in countless forms, each with different properties and recyclability. For instance, supermarket cling films made from PVC (Polyvinyl chloride) and LDPE (Low-Density Polyethylene) look similar, yet PVC contaminates current recycling streams, while LDPE does not. Without clear guidance and policy intervention, these barriers will continue to undermine progress.

The Way Forward: The scale of the plastic challenge may seem daunting, but there are actually clear priorities to address. Where do the emissions come from? A closer examination reveals key trends:

- 75% of plastic’s lifecycle emissions occur before the production of its main ingredients: polymers.

- 58% of total plastic emissions come from just three plastic types—PET (Polyethylene terephthalate), PP (Polypropylene), and PE (Polyethylene), in which they are mainly used for packaging. Packaging consumes nearly 40% of global plastic demand[4].

- Only 28% of plastics were recycled in the UK[5].

This means:

- If fossil inputs were to be avoided, 75% of plastic life cycle emissions could be addressed.

- If plastic demand for packaging were reduced, nearly 66% of total plastic emissions could disappear.

- There is still huge improvement to be achieved in end-of-life treatment.

Industry Actions: The UK market is actively addressing these challenges through impactful initiatives. A notable example is the UK Plastics Pact, led by the Waste and Resources Action Programme (WRAP). This collaborative effort unites businesses across the value chain to pilot innovative solutions and establish best practices. Alongside WRAP’s efforts, various industry players—including retailers, technology innovators, and waste management companies—are driving progress through independent and collaborative actions.

Specific initiatives being pursued across the sector include:

- Eliminating fossil inputs

Innovators are creating new plastic materials to reduce reliance on fossil fuels, primarily through two approaches: bio-based plastics and biodegradable materials (Figure 4).

- Bio-based plastics utilise organic sources such as starch (e.g., potatoes, corn), cellulose (e.g., sugarcane), chitin (e.g., mushrooms, seaweed), and materials produced by microorganisms. These alternatives aim to lower emissions by replacing fossil-based feedstocks.

- Biodegradable plastics are designed to decompose into natural substances under specific conditions. Among these, compostable plastics meet stricter criteria—they must break down without releasing toxins and can even support plant growth.

- Industrially compostable plastics require controlled conditions in composting facilities to degrade fully.

- Home compostable plastics can break down in well-maintained home composting systems.

Compostable plastics are especially promoted as a solution for hard-to-recycle, food-contaminated items like fruit stickers and tea bags. For instance, Waitrose partnered with WRAP to trial selling loose fruits without packaging, offering compostable plastics for customer use. This trial provided valuable insights, enabling WRAP to publish guidelines for retailers to encourage consumers to reduce plastic use[6].

2. Encouraging Impactful Recycling

Effective recycling is a cornerstone of the circular economy, preventing plastic waste from polluting the environment. Whilst all plastics are theoretically recyclable, economic and logistical barriers—such as cost, market demand, and collection efficiency—limit real-world recycling rates. PET and HDPE, commonly used in water and milk bottles, are the most recycled due to established markets and infrastructure. In contrast, multi-layered or contaminated plastics often end up in landfills or incineration because recycling them is not economically viable.

- Mechanical recycling, the traditional method, shreds and reforms plastics without altering their chemical structure. However, it requires clean, single-polymer plastics, making it unsuitable for contaminated or mixed materials. UK innovator LabCycle is improving sorting and decontamination technologies to recycle lab plastic waste instead of incinerating it.

- Chemical recycling breaks plastics down at the molecular level, enabling the processing of previously ‘unrecyclable’ materials. A leading example is Mura Technology’s Teesside-based chemical recycling plant. Set to begin operations this year, it has gained market traction for its ability to recycle mixed plastics more efficiently and cost effectively than many existing methods.

Chemical recycling should complement, not replace, mechanical recycling. While mechanical recycling is faster and more resource-efficient, chemical recycling addresses contamination and quality issues, ensuring more plastics remain in the circular economy.

3. Reducing the use of plastic – the Ultimate Solution

No single solution is perfect, each comes with trade-offs that must be carefully managed.

- Bio-based plastics offer an alternative to fossil fuel-based plastics, but large-scale production raises concerns about competing with food crops, shifting the environmental burden to land and water use[7].

- Compostable plastics face challenges in real-world conditions, where ideal degradation environments are often unavailable. They are also frequently treated as contaminants in conventional recycling facilities and suffer from misuse due to consumer confusion over terminology.

- Recycling, while essential, is not carbon-neutral—it still emits CO₂ and often requires virgin plastic inputs to maintain material quality.

These challenges reinforce the plastic waste hierarchy: reducing overall plastic demand must remain the top priority in building sustainable solutions.

Businesses need to prioritise reducing plastics’ environmental impact across their supply chains rather than making decisions based on broad assumptions about which materials seem “best” on the surface[8]. A strategic, evidence-based approach is critical for driving meaningful change. For example, Carbon Limiting Technologies is hosting roundtables for corporate leaders, providing in-depth research and industry examples to help reduce Scope 3 emissions. These insights are vital for businesses to develop effective strategies that deliver lasting progress in tackling waste and broader sustainability challenges.

Policy Opportunities for a Sustainable Plastic Economy: A truly circular economy would eliminate plastic use, reserving it only for essential applications—designed for reuse or made from compostable materials. Any unavoidable waste would be fully recycled into new plastics, ensuring nothing is discarded.

While this ideal scenario remains out of reach, innovative solutions are narrowing the gap between ambition and reality. Some UK businesses are already making promising strides towards sustainable plastic use. Policymakers have a vital opportunity to reduce plastic waste, improve recycling and incentivise sustainable alternatives by aligning regulation, investment, and public engagement towards a circular economy.

Key Actions for Policymakers

The UK has a unique opportunity to lead the global transition to a circular plastic economy. Here are five critical steps:

- Strengthen Regulations with Clear Terminologies

- Standardise labelling to differentiate between bio-based, industrially compostable, and home compostable plastics.

- Implement recycled content requirements and clear labelling regulations to improve transparency.

- Eliminate Problem Plastics

- Phase out harmful plastics like polystyrene packaging and PVC cling film.

- Enhance Extended Producer Responsibility (EPR) policies to hold manufacturers accountable for the entire lifecycle of their products.

- Mandate 100% Reusable, Recyclable, or Compostable Packaging

- Ensure all plastic packaging is designed for reuse, recycling, or composting.

- Clarify EPR rules to encourage simplifying packaging designs to make recycling more efficient.

- Accelerate Investment in Recycling Infrastructure

- Expand mechanical and chemical recycling capacity to handle complex plastic waste.

- Support innovations like Mura Technology’s chemical recycling plant, which can process previously unrecyclable materials.

- Foster Cross-Sector Collaboration

- Encourage partnerships between government, industry, and researchers to share case studies and knowledge to drive systemic change by establishing clear guidelines.

- Build on initiatives like the UK Plastics Pact, which brings together businesses to trial sustainable solutions.

The time for action is now. Plastic pollution is a global crisis that demands immediate, bold, and unyielding action. By implementing clear, stringent regulations, enforcing uncompromising producer accountability, and investing in ground-breaking innovative solutions, the UK has the opportunity to establish itself as the market leader in the battle against plastic emissions and pollution.

[1] European Environment Agency | Plastics.

[2] Climate Impact of Primary Plastic Production, Lawrence Berkeley National Laboratory (2024).

[3] The Circular Economy for Plastics, Plastics Europe (2024)

[4] The Circular Economy for Plastics, Plastics Europe (2024)

[5] The Circular Economy for Plastics, Plastics Europe (2024)

[6] Delivering Impact Together – Annual Report 2024, WRAP (2024)

[7] The Unintended Side Effects of Bioplastics: Carbon, Land, and Water Footprints, Brizga, Janis et al. (2020)

[8] Waste and Resources Action Programme.

This article will be published in the 2025 Summer edition of The Parliamentary & Scientific Committee’s quarterly journal, Science in Parliament. The full edition is available to Members only, but we have received permission from the Committee to repost the standalone article.

Melody Chiu is a climate tech analyst at Carbon Limiting Technologies (CLT), a London-based innovation consultancy supporting the commercialisation of low-carbon technologies. Melody specialises in decarbonisation technology research across industries such as sustainable materials, hydrogen, batteries, concrete, and critical minerals. With expertise in evaluating innovation ecosystems through data research and framework analysis, Melody has extensive experience in developing net-zero strategies to tackle complex market challenges by leveraging innovation, investment, and policy engagement. She holds an MPhil in Industrial Systems, Manufacture and Management from the University of Cambridge, where she gained deep knowledge of technology commercialisation and innovation dynamics. Her multinational experience across Europe and Asia informs her approach to scaling solutions in diverse market contexts.

Chris Rapley CBE MAE is Professor of Climate Science at University College London and a Fellow of St Edmund’s College Cambridge. He is Chair of the UCL Climate Action Unit, a member of the Advisory Board of the UK Clean Growth Fund, Patron of the Surrey Climate Commission, and a member of the Parliamentary and Scientific Committee. He holds additional roles such as Chair of the European Science Foundation’s European Space Sciences Committee. His previous posts include Directorships of the UCL Mullard Space Science Laboratory’s Earth Observation Research, the International Geosphere- Biosphere Programme, the British Antarctic Survey, and the Science Museum. He began his career as a space scientist at UCL’s Mullard Space Science Laboratory investigating the X-ray cosmos, Solar flare X-ray emissions, and the use of polar orbiting satellites to revolutionise the study the Earth as an integrated system.

Written by