Introduction

Plastic pollution is one of the biggest environmental threats in the 21st century. Most plastics are still made from fossil fuels and do not break down in nature, persisting in soils, waterways, and oceans, notoriously known as microplastics.

Plastics’ climate significance is not marginal: across the value chain, they represent around 4.5% of global carbon emissions[1] (Read our other insight article to learn more on the carbon emissions impact from the plastic industry: More Than Trash: The Carbon Cost of Plastic). Most plastics in circulation today are still fossil-based, dominated by polyethylene (PE), polypropylene (PP) and polyethylene terephthalate (PET), making up 58% of total plastics production[2]. Recent analysis estimates that around 98% of virgin plastics were fossil-derived in 2022[3], underscoring the scale of dependency. People started to wonder if biodegradable and bio-based plastics are the answer to this problem?

Moreover, policy is responding to the plastic issue by reshaping what a “plastic-free future” looks like. The direction of travel is clear: eliminate unnecessary plastic use, design necessary applications by using alternative materials, and recycle when unavoidable.

EU Packaging and Packaging Waste Regulation 2025/40 (PPWR): what it changes and when

In the EU, the Packaging and Packaging Waste Regulation 2025/40 (PPWR) codifies this shift through recyclability requirements, recycled-content targets, and defined use-cases for certified compostable plastics, setting a long-term roadmap for industry and government. PPWR entered into force on 11 February 2025.

Current measured outcomes are falling behind the ambition. In 2022, Plastics Europe reported that only 26.9% of plastic waste in Europe was recycled[4]. This reality gap underscores how material choices, product design and end-of-life systems must align before circularity claims can hold.

Consumer attitudes to plastic choices

Consumers are shifting too. Evidence shows they are willing to pay for packaging they perceive as sustainable and are unwilling to pay for options seen as non-sustainable or uncertain, despite recognising some practical benefits of single-use plastics. Consumers are also largely united in dissatisfied with the current packaging situation[5].

For businesses, this convergence of regulation, system gap and customer expectation elevates plastics strategy to a high-level priority, what are the more sustainable options out there to replace conventional plastics?

What are bio-based and biodegradable plastics?

“bioplastics” is compelling—but only in the right contexts.

The term “bioplastics” is often seen on packaging and can sound like a simple fix to the plastic problem, but it bundles together two different ideas and is often misunderstood. Before considering these plastics, it helps to clarify the two terms most often conflated in the market.

Bio-based vs biodegradable: what is the difference?

Bio-based and biodegradable plastics are in fact two very distinct concepts.

- “Bio-based” refers to feedstock origin (wholly or partly from biomass)

- “Biodegradable” refers to a material’s end-of-life. The ability of the plastics to be broken down by microorganisms into water, CO₂ and biomass under specified conditions.

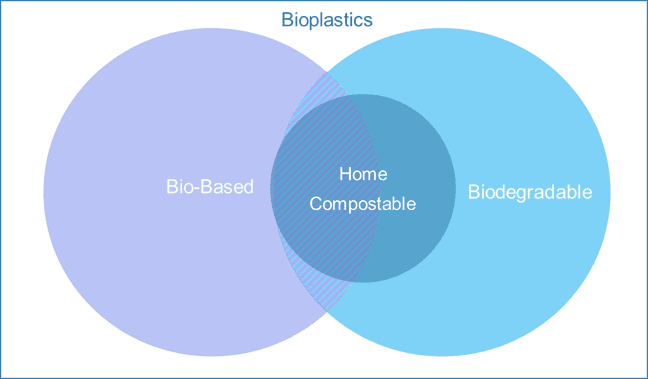

The confusing part here is that plastics that are either bio-based, biodegradable, or both, are all called bioplastics (See figure below).

‘Biobased’ does not equal ‘biodegradable.’

Biodegradability depends on the polymer structure and treatment conditions, not on whether the raw materials came from plants or fossil fuels. A 100% bio-based PET is still PET and is not inherently biodegradable; conversely, some fossil-derived polymers can biodegrade when the right conditions are met.

Polyvinyl alcohol (PVOH) illustrates the nuance. Commonly used as a water-soluble film in dishwasher and laundry pods, PVOH is typically fossil-based yet can be biodegradable under controlled conditions. Its fate in real-world wastewater systems is still being examined, which highlights a broader lesson: performance hinges on system conditions and end-of-life pathways, not labels alone.

What are Bio-based plastics? Definition and common types

Plastics made wholly or partly from biomass can reduce reliance on fossil feedstocks and, in some cases, improve Scope 3 emissions. Common bio-based plastics include:

- Starch-based materials: Considered the most suitable for food packaging because they are biodegradable, low cost, and easy to process into films with good mechanical properties. Common sources are potatoes, wheat, and corn. Sensitivity to moisture remains a limitation, and products are often opaque or semi-transparent, which can restrict applications[6].

- Microorganism developed materials: Produced via fermentation and are mostly compatible with most conventional plastics processing equipment. PLA is the second most produced biodegradable bioplastic, after starch blends, and has properties similar to PE and PP[7]. PLA is biodegradable under industrial composting conditions (typically elevated temperature and aeration) but not in ambient environments, so access to appropriate infrastructure is critical.

- Cellulose-based materials: Commonly derived from plant fibres (e.g., rice straw, sugar cane) with strong stiffness/strength profiles in certain formats. Typically, cellulose is highly crystalline and hydrophilic, producing brittle packaging material that cannot be used for packaging purposes due to poor flexibility and tensile strength.

- Chitin-based: Commonly sourced from mycelium or seaweed. This material is most used for rigid protective packaging such as alternatives to polystyrene (PS) and expanded polystyrene (EPS).

Beyond early-stage cost and scale frictions, the feedstock availability poses a huge concern. A research by the University of Groningen estimated that replacing all packaging plastics with bioplastics would require around 54% of current global corn production, illustrating land-use pressures if substitution is pursued without demand reduction and secondary feedstocks[8].

There are ways to mitigate this problem: using biowaste instead of crops as feedstock input can materially reduce feedstock costs. Some studies estimated that it is possible to reduce 50% of production costs[9], as well as shrinking the water and land footprints, though supply consistency and process control remain hurdles. Without careful system design, shifting burdens to land and water is a real risk.

What are Biodegradable plastics? Definition and common types

Plastics become a pollution problem at end of life because many formats are hard to recover, especially light, flexible, and food-soiled items that evade collection or contaminate recycling streams. When these materials are mismanaged, they stay in soils and waterways, fragmenting into microplastics.

Against that backdrop, biodegradable plastics are compelling because they are designed to break down into water, carbon dioxide (or methane), and biomass under specified conditions. when they are collected and treated in the intended system, they can avoid persistence and reduce contamination for items that are typically difficult to recycle mechanically.

Those specified conditions include temperature, duration, the presence of microorganisms, nutrients, oxygen, and moisture[10][11]. Compostable materials meet stricter criteria, including disintegration and lack of ecotoxicity in compost.

According to the European Environment Agency (EEA)[12], plastics can be categorised into:

- Biodegradable plastics: designed to biodegrade in a specific medium (water, soil, compost) under certain conditions and in varying periods of time.

- Industrially compostable: designed to biodegrade in the conditions of an industrial composting plant or an industrial anaerobic digestion plant with a subsequent composting step.

- Home compostable: designed to biodegrade in the conditions of a well-managed home composter at lower temperatures than in industrial composting plants. Most of them also biodegrade in industrial composting plants.

These materials often carry cost premiums at current scale and can have different mechanical or barrier properties compared with conventional plastics. Critically, when mis-sorted they can contaminate recycling streams, a systems issue that can be mitigated by clear labelling and collection design but not solved by materials alone. Current infrastructure still needs huge improvements to emphasise careful scoping and communication.

Under PPWR, by 12 February 2028 formats such as tea and coffee bags, and stickers on fruits and vegetables must be compatible with at least industrial composting. Prioritising these applications aligns materials with policy and real end-of-life pathways.

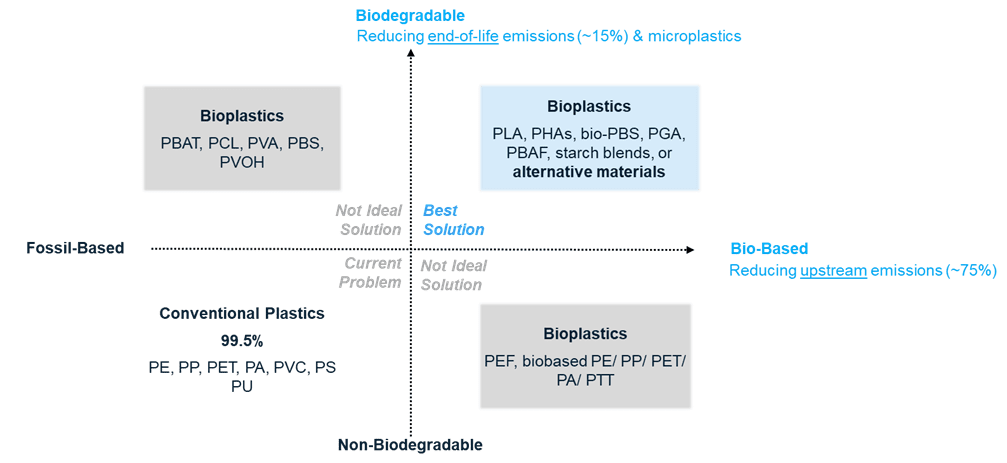

Below figure summarises the different types of plastics.

Future of sustainable plastics: towards a circular economy

Neither bio-based nor biodegradable plastics can, on their own, “solve” the plastics problem. Demand reduction, better reuse, credible recycling, and targeted compostability each have roles, calibrated to format, context and system, with policy increasingly providing the alignment.

Addressing the limits of today’s options will depend on feedstock innovation, system design and standardisation, and careful prioritisation of applications. Secondary inputs (agri-food waste, industrial residues, marine biomass) can ease reliance on primary land and reduce feedstock costs, but supply stability and quality control must be proven at scale. Claims about biodegradation rates also needs contextualisation and clearer labelling. Finally, prioritise the applications where conversion delivers the greatest system benefit.

There is no single answer. A mature circular system eliminates the unnecessary, designs the necessary for reuse or clearly defined end-of-life (for instance, mechanical recycling where possible; certified composting where it is the most credible route), and recovers unavoidable waste into new materials. For corporate leaders, the task is to stay literate in the evolving materials and policy landscape, align specifications with real infrastructure, and communicate claims that hold up in the field as well as in standards. In practice, it is how firms convert regulatory momentum into long-term value.

FAQ:

- What is the difference between bio-based and biodegradable plastics?

Bio-based refers to the origin of the carbon (wholly or partly from biomass). Biodegradable refers to the end-of-life of the material. The two are not the same: a 100% bio-based PET is not inherently biodegradable, while some fossil-derived polymers can biodegrade in the right system.

- Are biodegradable plastics really eco-friendly?

Depends. when they are used in the right applications and routed to the intended treatment system. Biodegradable plastics are designed to break down under specific conditions (e.g., industrial composting); outside those conditions, benefits diminish, and they can even contaminate recycling streams. Eco-performance is therefore context-dependent and hinges on both applications’ choice and end-of-life pathway.

- What does the EU PPWR regulation mean for businesses?

Packaging and Packaging Waste Regulation 2025/40 (PPWR), entered into force on 11 February 2025, tightens design rules across the EU by mandating recyclability, setting recycled-content targets, and defining where certified compostable formats are appropriate. It also introduces dated obligations, such as evaluating industrial-compostability requirements for certain items (e.g., permeable tea/coffee bags and fresh-produce labels) by February 2028. Companies claims and supplier contracts need to align with those timelines.

- Can biodegradable plastics replace single-use packaging?

Not completely. They can be effective for specific, food/bio-contaminated, or hard-to-recycle formats when collected and treated in the intended system, but they are not a universal substitute for all single-use plastics. Eliminate, reuse, and design-for-recycling remain primary routes in most cases, with compostables reserved for well-defined use-cases.

References:

[1] Climate Impact of Primary Plastic Production, Lawrence Berkeley National Laboratory (2024).

[2] Climate Impact of Primary Plastic Production, Lawrence Berkeley National Laboratory (2024).

[3] Houssini, K., Li, J. & Tan, Q. Complexities of the global plastics supply chain revealed in a trade-linked material flow analysis. Commun Earth Environ 6, 257 (2025). https://doi.org/10.1038/s43247-025-02169-5

[4] The Circular Economy for Plastics, Plastics Europe (2024)

[5] Lin, J., Jaiswal, A. K., & Jaiswal, S. (2025). A Critical Review of Consumer Perception and Environmental Impacts of Bioplastics in Sustainable Food Packaging. Sustainability, 17(4), 1358. https://doi.org/10.3390/su17041358

[6] Lin, J., Jaiswal, A. K., & Jaiswal, S. (2025). A Critical Review of Consumer Perception and Environmental Impacts of Bioplastics in Sustainable Food Packaging. Sustainability, 17(4), 1358. https://doi.org/10.3390/su17041358

[7] Same as above

[8] Brizga, Janis et al. The Unintended Side Effects of Bioplastics: Carbon, Land, and Water Footprints. One Earth, Volume 3, Issue 1, 45 – 53

[9] Ghasemlou, M.; Barrow, C.J.; Adhikari, B. The future of bioplastics in food packaging: An industrial perspective. Food Packaging and Shelf Life 2024, 43, 101279.

[10] De Wilde, B., Mortier, N., Verstichel, S., Briassoulis, D., Babou, M., Mistriotis, A., & Hiskakis, M. (2013). Report on current relevant biodegradation and ecotoxicity standards.

[11] van den Oever, M., & Molenveld, K. (2017). Replacing fossil based plastic performance products by bio-based plastic products—Technical feasibility. New biotechnology, 37, 48-59.

[12] https://www.eea.europa.eu/en/analysis/publications/biodegradable-and-compostable-plastics-challenges-and-opportunities

Written by